Business Practices

As a responsible company, Myanma Awba strives to do the right thing when we engage with our business partners and suppliers or manufacture our products. We ensure that our operations comply with all relevant rules and regulations.

Business Integrity

Safeguarding the integrity of our Group is paramount.

Our Code of Ethics defines how our employees should perform their work. Myanma Awba encourages all its stakeholders to report their concerns – it is key for us to identify and manage all our risks related to ethics.

Eco-efficient Manufacturing

To manufacture our products, we rely on materials, energy and water. By optimising the efficiency of our industrial processes and monitoring our impacts carefully as set by our policy, we aim to minimise our environmental footprint – what is good for the planet is also good for our business. We are working to save energy and save as much waste as possible.

Value Chain Management

We work closely with various partners to import raw materials and transform them into finished products, and with 900+ distributors to reach hundreds of thousands of farmers across the country.

We assess our risks and engage with all the different actors who are essential for delivering value to Myanmar’s farmers through our products.

Human Rights

Myanma Awba is committed to respecting human rights. We assess risks related to human rights and ensure that we can provide effective remedies whenever needed.

Highlights for FY 23/24

- We recorded 9 breaches of our Code of Conduct.

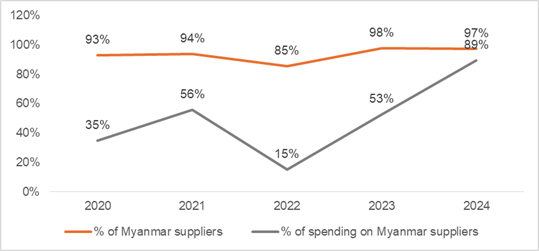

- 97% of our suppliers are Myanmar businesses.

- 89% of our spending went on Myanmar suppliers, an increase from 53% last year.

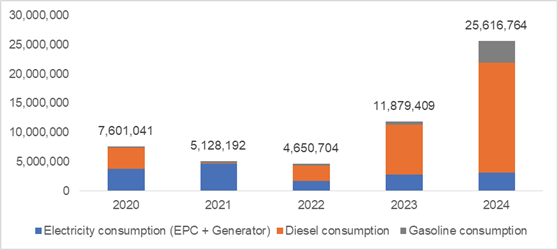

- We consumed 25,616 MWh in 2024, from which 94% of our energy consumption comes from diesel.

- Our total energy consumption increased by twice in FY23/24 compared to FY22/23, as the electricity supply from EPC continues to be significantly lowered.

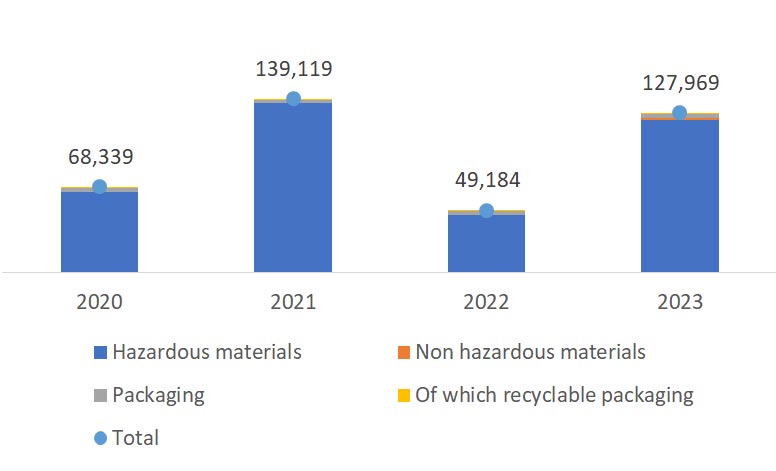

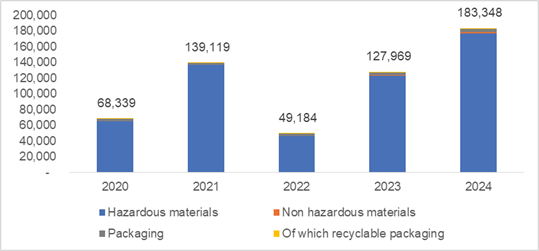

- We consumed 183,348 tons of raw materials, of which 97% were hazardous materials.

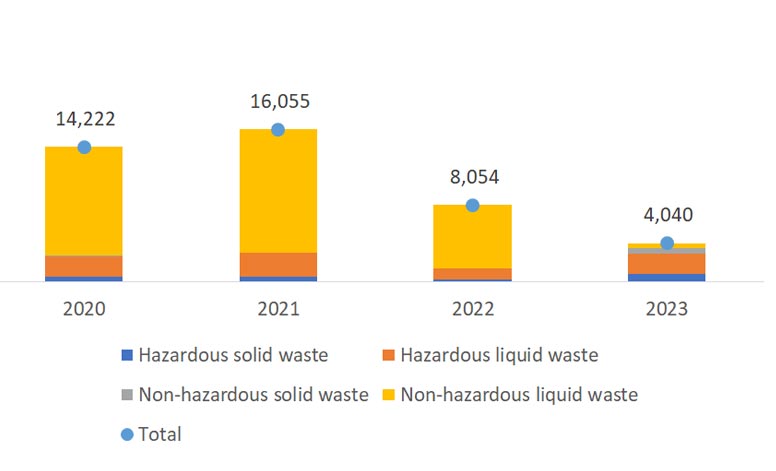

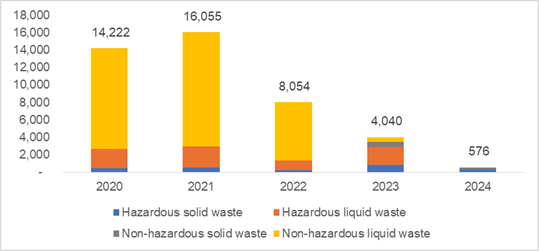

- Our total production of waste decreased by -86% in 2024.

- 76% of our waste was recycled, 3% were recovered, and 21% were landfilled respectively.

- We consumed 61,228 cubic meters of water and discharged 1,724 cubic meters.

- We are committed to respecting human rights, and regularly assess risks related to our people, partners and customers.

Evolution of our materials

consumption (tonne)

Evolution of our waste production

(tonnes)

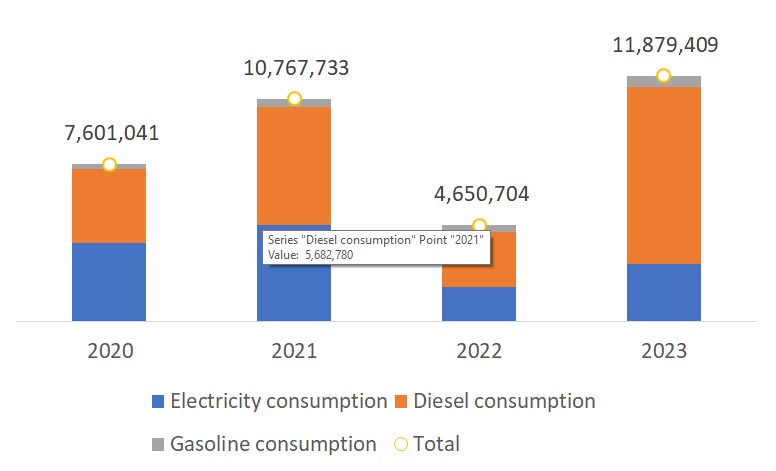

Evolution of our energy

consumption (kwh)

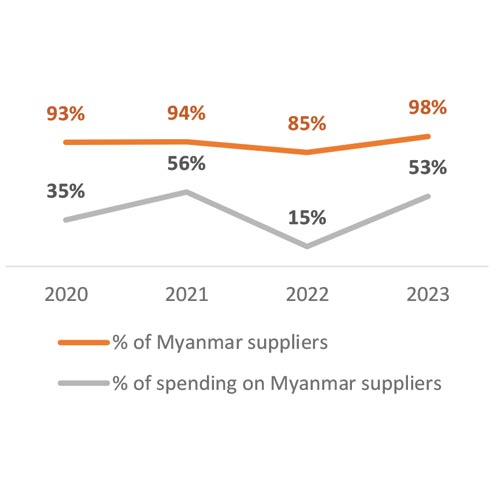

Evolution of our supply chain

Highlights for FY 21/22

- We did not receive any alerts related to our Code of Ethics in FY 21/22. We received one during the previous financial year.

- Our energy consumption reached 4,650 MWh in FY 21/22, while our monthly consumption decreased by 14% compared to FY 20/21. Today, we rely mostly on diesel to power our operations and move our fleet of vehicles.

- We consumed 17,514 cubic meters of water in FY 21/22, and our monthly consumption remained stable compared to FY 20/21. Likewise, we withdrew on average 80% of the water we need for our operations from sources near our production sites.

- To manufacture our products, we used 69,836 tonnes of materials, of which 66% were hazardous materials. Our activities generated 8,053 tonnes of waste, of which 17% was hazardous waste.

- In FY 21/22, we worked with 638 suppliers, of which 85% were Myanmar businesses, compared to 94% in FY 20/21. In terms of spending, the Myanmar suppliers represented 15% of our total expenditure in FY 21/22, compared to 56% in FY 20/21. This trend reflects the devaluation of the kyat: we had to spend more kyat to buy dollars in 2021 and 2022.

- Since October 2020, we have received a total of 10 complaints. Our team investigated and resolved all of them. Despite adverse conditions, we have always managed to deal with cases in a timely manner and to meet our targets. All of those who submitted complaints were satisfied with our process, and more than 80% with the outcome.

Evolution of average energy consumption (MWh/month)

Evolution of water consumption

(average m3/month)

* In cubic metres

Breakdown of the materials used for our operations

Breakdown of our waste

Evolution of our supply chain

Grievance Mechanisms

* In days

Environmental and Social Impact Assessment

AWBA Group hears and understand the concerns of the villagers of Hmawbi Township and is therefore committed to ensuring our plant – Hmawbi Agricultural Input Complex (HAIC) – are in line with international health, safety and environment standards.

To this end, we engaged a third-party to conduct an Environmental and Social Impact Assessment (ESIA) based on the Environmental Laws of 2003.

After revised environmental regulations were put in place by the Ministry of Environment in December 2015, we conducted a new ESIA with the guidance of the International Finance Corporation (IFC). This latest assessment is complete and submitted to the Myanmar Investment Commission and the Ministry of Natural Resources and Environment.

Myanma Awba Group received the Environmental Compliance Certificate (ECC-1016) for HAIC in October 2024 ,Ref: EIA-3/2/ECC(EIA)(4944/2024), confirming compliance with Myanmar’s Environmental Conservation Law, EIA Procedure requirements, and commitment to sustainable, responsible operations.

To this end, we engaged a third-party to conduct an Environmental and Social Impact Assessment (ESIA) based on the Environmental Laws of 2003.

After revised environmental regulations were put in place by the Ministry of Environment in December 2015, we conducted a new ESIA with the guidance of the International Finance Corporation (IFC). This latest assessment is complete and submitted to the Myanmar Investment Commission and the Ministry of Natural Resources and Environment.

Grievance Mechanisms at Work in Hmawbi Community

What is a Grievance Mechanism?

A tool developed to create healthy and informative communication between project-affected community members and AWBA, should a complaint or suggestions arise.

AWBA’s Unique Beliefs and Approach

- Training community volunteers

- Utilising engaging tools such as cartoons to effectively teach

- Posting a sign board and distributing informational pamphlets to community

How They Work

Create two-way communication between community members and AWBA

Ensure community members are given a voice

Mitigate and manage risks associated with the project

Obtain social licence to operate in the community

Community Volunteers

Community volunteers from the village are selected in order to inform their community about new methods for reporting complaints and suggestions, known as grievance mechanisms. They are key in liaising between the community and the respective business.

Wa Net Chaung Ywar Ma

Wa Net Chaung Ywar Ma

Daw Na Kone Village group